|

You've got a point

Robot controllers are very smart. They can drive a robot in

perfect interpolation (all the joints starting and stopping

together in smooth motion). You just give them points and they

will create the actual motion.

Uh, right, you just give them points...

Where do the points come from? In manual teaching, you drive

the robot and declare a point at any desired position in

space, and it is the duty of the robot controller to connect

all the points in an imaginary smooth curve.

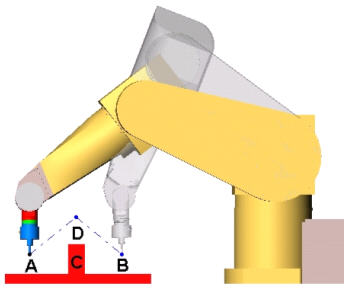

However, robot controllers have logic of their own. Left to

their own devices, the tool will move between point A and B

through object C. You should have entered a point D in mid air

above the object, but you didn't. And it's hard to blame you,

since most cases are far less obvious and 3D vision is not

common among humans.

No one can really envision each and every intermediate

position of every robot part along the way. High-end robot

simulation programs can, but not every plant is General

Motors.

Enter RobotWorks, the real power behind the path.

Make a simple sketch from A to B through D, extrude -

finished. You saved your face, literally.

Inside SOLIDWORKS the faces you picked may be very different

mathematically. Not only it is possible to create the same

face in more then one way, but solid geometry can create

strange and hard to envision faces (think of face blend or

loft with guide curves...). Moreover, during your design you

change parts position and orientation, add or edit parts, and

may end up looking at an assembly that does not resemble a

path at all.

RobotWorks internal algorithms take care of all that for you.

Not only does it connect all the faces into one long path; it

also applies points evenly along the faces. You set a pitch

(distance between points) to each part, feature or face, or

use default one for the whole path. Every point is calculated

according to the feature it is on and then saved with the

related location and orientation data.

Download this

article in PDF

|

![]()

![]()